Rayleigh sprays

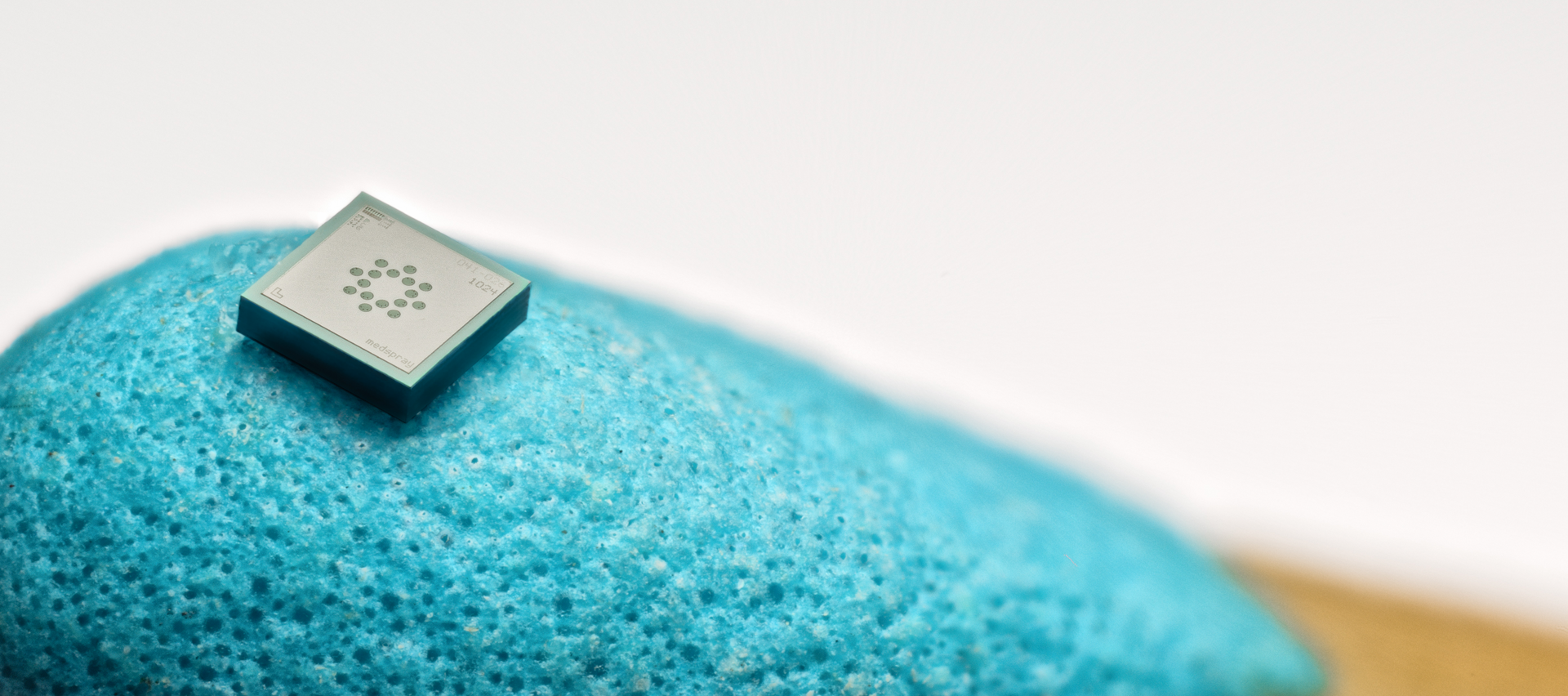

Medspray owns six patent families concerning the spray nozzle unit technology. Our spray nozzle units are based on plain orifice nozzles, creating Rayleigh jets. A 2 micron hole creates a jet, breaking up into mono-disperse (meaning all droplets have the same size) 4 micron droplet trains. The diameter of the droplets is twice the size of the orifice. The hole size can be engineered to meet specific requirements of devices. Spray nozzle chips are made with technologies generally seen in computer chips, but our chips do not have electronic functions, they are purely a mechanical structure.

Pressing water through the Medspray nozzle results in a jet which automatically breaks up in droplets (Rayleigh breakup). The spray is mono-disperse. All droplets are twice the size of the hole. By changing the diameter of the hole in the spray nozzle, the droplet size can be engineered for optimal performance.